Home > Products > Cartridge Heaters > Technical Information

Cartridge heaters by Thermal Corporation may be used for many heating applications, but they are most often used to heat blocks of metal (such as dies on injection molding machines) by insertion into drilled holes in the metal. When used in this application, the major factors influencing heater lifetime are the watt density on the heater surface, the fit in the hole and operating temperature.

Cartridge heaters are also used for the heating of water and water-based liquids of low viscosity by the addition of a threaded header on the lead-end of the heater. The small size and big capacity of swaged cartridge heaters make them ideal immersion heaters in cramped quarters. For water heating applications, a rating of of 150 to 300 watts per square inch is recommended (much higher ratings are possible for conditions of high water flow rate over the heater.

_______________________________________

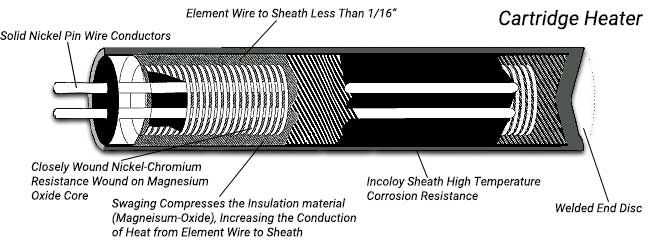

Construction of a Cartridge Heater

(Excerpted from Wikipedia)

Heating coil

The heating coil is the actual resistance which is where the electrical load occurs. The most common type of metal alloy used for this purpose is a Nickel-Chromium mixture, also known as Nichrome. the Nichrome wire is wound around a ceramic core, and the number of spirals per inch vary according to the requested watt density. Potential from an alternating current source, which can either be 2 phase or 3 phase, flows through the coiled Nichrome wire, heating up the wire, which in turn, heats the cartridge heater sheath.

Insulation

Insulation is used to prevent the Nichrome coil to contact the sheath. If such event happened, it would ground the resistance and potentially produce a catastrophic short-circuit, resulting in a melted sheath and a major equipment failure. Damage can be mitigated by installing a ground fault interrupting circuit. To prevent the coil from touching the sheath, the coil is inserted into the sheath, and immediately filled with Magnesium Oxide (MgO). To ensure the MgO fills the empty space between the sheath and the coil, the cartridge heater is vibratory filled.

Sheath

The sheath is the part of the cartridge heater which makes contact with the material or substance to be heated. Several metal alloys are used, depending on the type of application, such as highly acidic or corrosive environments. The most common types of sheaths are 304 Stainless Steel, 316 Stainless Steel, and Incoloy 800. Incoloy has the highest temperature rating, it is considered a Superalloy.

Sealing

After the cartridge heater has been filled with MgO, a seal is applied to the open end of the cartridge heater (where the Nicrome coil was introduced), this prevents the coil and the MgO from coming out. Also, it prevents contamination, such as plastic debris, air, or moisture, to go inside the heater.

Termination

Since cartridge heaters are installed in a wide variety of machines, manufacturers must design the heaters to meet certain clearances. The cartridge heaters might be terminated with the leads coming out straight, or in a right angle. Also, manufacturer must be careful that the leads are not exposed to temperatures higher than the maximum rating for the lead wire. In order to prevent lead wire damage from temperature, movement or contamination, the lead wire can be protected with metal conduit, braided metal or silicone sleeves.

Lead wire type

Depending on the clearance and the design of the machine where the cartridge heater will be inserted, the type of wire used will vary. Fiberglass is the commonly used for cartridge heaters and other high temperature applications, such as automotive wiring harnesses and industrial equipment. Other variants used are silicone impregnated fiber glass and silicone rubber.

Written by Jennifer Taylor & Shelby Reece

Date Published: 01.17.2014

Last Updated: 03.11.2020